The Only Guide for Insulated Glazing Panels

Table of ContentsThe Best Guide To Glazing Infill PanelsThe Buzz on Glazed Spandrel PanelNot known Details About Large Double Glazed Glass Panels Glazing Panel Fundamentals Explained

Regulated water penetration is specified as water that penetrates beyond the inner most vertical plane of the test specimen, however has actually a created means of drain back to the outside. AAMA Voluntary Specifications allow for regulated water penetration while the underlying ASTM E1105 test method would define such water penetration as a failure.This set up replicates a wind driven rain event on the curtain wall to check for field efficiency of the item and of the setup. Field quality assurance and assurance checks for water penetration has actually ended up being the standard as builders and installers apply such quality programs to help in reducing the variety of water damage litigation matches versus their work.

This equates to three times more deflection in an aluminum mullion compared to a similar steel area under a provided load. Structure specifications set deflection limitations for perpendicular (wind-induced) and in-plane (dead load-induced) deflections. These deflection limits are not imposed due to strength capabilities of the mullions. Rather, they are designed to restrict deflection of the glass (which may break under excessive deflection), and to guarantee that the glass does not come out of its pocket in the mullion.

Building building might be such that there is a wall situated near the mullion, and extreme deflection can trigger the mullion to get in touch with the wall and cause damage. Likewise, if deflection of a wall is quite visible, public understanding might raise undue concern that the wall is not strong enough - glazing infill panels.

What Does Glazing Panel Mean?

A deflection limitation of L/175 prevails in curtain wall specifications, based on experience with deflection limitations that are unlikely to cause damage to the glass held by the mullion. Say a given curtain wall is anchored at 12 foot (144 in) floor heights. The allowed deflection would then be 144/175 = 0.

823 inches at the maximum wind pressure. However, some panels need stricter motion limitations, or definitely those that prohibit a torque-like movement. Deflection in mullions is managed by various shapes and depths of drape wall members. glazed spandrel panel. The depth of a given curtain wall system is typically managed by the location minute of inertia required to keep deflection limitations under the spec.

The allowed flexing strength for specific aluminum alloys, such as those normally utilized in curtain wall framing, approaches the allowable flexing strength of steel alloys utilized in structure construction. Relative to other building components, aluminum has a high heat transfer Check This Out coefficient, suggesting that aluminum is a great conductor of heat.

Not known Facts About Large Double Glazed Glass Panels

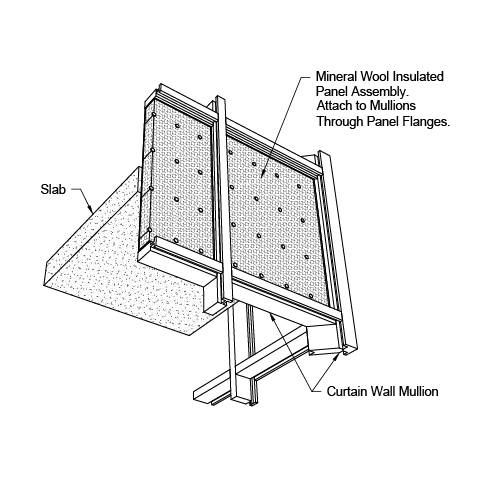

On an inadequately performing curtain wall, condensation may form on the interior of the mullions. This might cause damage to surrounding interior trim and walls. Rigid insulation is offered in spandrel locations to provide a higher R-value at these locations. Infill describes the big panels that are placed into the drape wall in between mullions.

The 1 inch insulation glass is normally made up of two 1/4-inch lites of glass with a 1/2 inch (12 mm) airspace. The air inside is generally atmospheric air, however some inert gases, such as argon or krypton might be used to use much better thermal transmittance values. Drape wall architecture building In property building and construction, densities typically utilized are 1/8 inch (3 mm) monolithic and 5/8 inch (16 mm) insulating glass.

Examine This Report about Glazing Infill Panels

Glass might be used which is transparent, translucent, or nontransparent, or in differing degrees thereof. Transparent glass normally describes vision glass in a drape wall. Spandrel or vision glass might likewise consist of translucent glass, which could be for security or aesthetic functions. Opaque glass is utilized in areas to conceal a column or spandrel beam or shear wall behind the curtain wall.

Shadow box construction produces a perception of depth behind the glass that is sometimes preferred. Fabric is another type of material which is typical for drape walls. Fabric is often much more economical and pins for spandrel insulation price works as a less permanent solution. Unlike glass or stone, material is much faster to set up, less costly, and frequently a lot easier to modify after it is installed.

Thin blocks (3 to 4 inches (75100 mm)) of stone can be inset within a drape wall system. The kind of stone used is limited only by the strength of the stone and the capability to make it in the proper sizes and shape. Common stone types utilized are: calcium silicate, granite, marble, travertine, and limestone (large glazing panels).

Metal panels can take various kinds including aluminum plate; aluminum composite panels including two thin aluminum sheets sandwiching a thin plastic interlayer; copper wall cladding, and panels consisting of metal sheets bonded to stiff insulation, with or without an inner metal sheet to produce a sandwich panel. Other nontransparent panel materials include fiber-reinforced plastic (FRP), stainless steel, and terracotta.